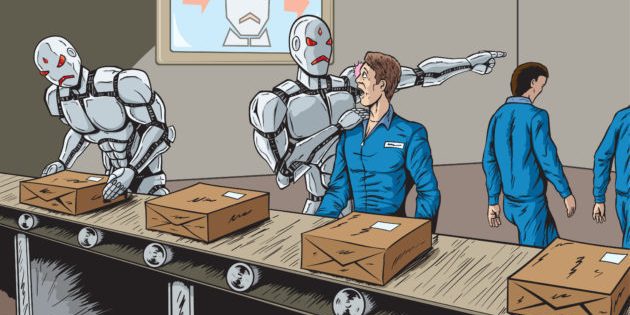

In the last 15 years the sale of automata in the world has increased by 500%, and according to the forecasts of “Viva la Robolution” -research published by Trademachines, a B2B platform for e-commerce in used industrial and agricultural machinery- by 2099 70% of workers will be automated.

Nevertheless, in the opinion of the researchers, this robotic invasion is not – and cannot be – a reason for unemployment, but on the contrary will increase both the productivity of companies and employment opportunities. For demonstration purposes, the situation in Germany, the world’s third largest market for robotics, is shown, where the unemployment rate from 2009 to 2015 declined by 37%. Another figure in favor of this thesis, according to Trademachines’ surveys, is the 1.5 million jobs created, thanks to robots, in the American automotivefield.

In Italy, too, the opinions of experts do not differ greatly: the general idea is that the imminent problem to be faced does not gravitate around the risk of an occupational shortage due to the increasingly massive introduction of robots into the working environment, but rather to the lack of awareness, on the part of many Italian companies, that digitalization is now a necessity and that, as a consequence, there is an urgent need to invest in young people, providing them with the education necessary to master the skills to occupy that multitude of emerging professions inextricably linked to technology and automation. Progress pushes in this direction, and the present demonstrates it: as already happened 200 years ago with the industrial revolution -where about 99% of agricultural workers were mechanized- today, with an 80% automation in the production process of a machine, the past seems to re-propose itself in “futuristic” clothes.

Currently, at a global level, the “automotive” sector absorbs 43% of the robots in circulation, 70% of which are distributed by China, Japan, South Korea, USA and Germany, but in the coming years automation will involve the vast majority of production sectors and industrialized countries embracing, in addition to large companies, also medium and small companies. It is therefore necessary to continue to deepen the design and manufacture – already in place – of machines capable not only to perform “blindly and repetitively” an assigned task, but to “interact” with the human element by supporting it in the performance of daily tasks. “Intelligent” robots, able to learn and modify themselves as needed and equipped with sensors that allow them, thanks to the watch and learn technology, to perceive the surrounding space and coordinate movements allowing the operators who work alongside them to operate in total safety. In order to summarize the characteristics and functions of such robots, the term Cobot was coined: robots certified to work in close contact with humans. In this regard was born in Europe, at the beginning of this year, the project ANDY -Advancing Anticipatory Behaviors in Dyadic Human-Robot Collaboration- coordinated by the researcher IIT (Italian Institute of Technology based in Genoa) Francesco Nori and co-funded by the European Union under the Research and Innovation Horizon 2020 program. The project has a duration of four years, involves research institutes and international companies in Italy, France, Germany, the Netherlands, Denmark and Slovenia, (e.g. ABB, Inail, FCA, Audi, Renault, Airbus) and is aimed at developing the adaptive, collaborative, perceptual and interactive qualities of robots in both industrial and domestic environments, interpreting human physical needs and reducing the risk of injury. These skills will be transferred into three different types of robots, realized in as many steps. The first type, the “simplest” to realize, is that of the cobot, whose core operation will be based on a sensorized suit worn by the person and connected to an external robot that, through the information transmitted to it, will interpret the difficult situations of the worker, intervening with simple actions to help him in his tasks and preserve him from accidents. The second step will take the form of an exoskeletonintegrated with extremely compact sensors, created for the purpose of being worn directly by humans. Through this instrument the individual – a sort of cyborg – will be supported, empowered and eventually corrected in movements. The exoskeleton will strengthen the human body, identifying and recommending the best postures according to the activities performed and preserving it from accidents due to situations of excessive skeletal-muscular effort. Thanks to its characteristics, it can also be used in the medical-rehabilitation field. The last and third step, the most complex and extraordinary of the entire project, will be the development of cognitive robots such as iCub (also built by the IIT of Genoa. 104 cm tall and weighing 22 kg), increasing their ability to perceive and anticipate human behavior. Final goal: to “give life” to an android capable of rapidly adapting to the greatest number of possible everyday contexts, reacting promptly and appropriately to human and environmental stimuli. Should the project succeed, besides representing a huge step forward in the field of AI, in the (perhaps) near future robots will be able to serve as caregivers (for the elderly, disabled and children), domestic helpers, companion “ladies” and who knows what else…

Judging from these premises and from the huge amount of energies lately oriented – in Europe as well as in the rest of the world – towards the horizons of automation and AI, it seems that the time is almost ripe for the most unrestrained sci-fi movies with a 70s/80s aftertaste to become for the good (C-3P0; Star Wars) orfor evil (T-800; Terminator) a tangible reality…

Marcello Argenti